SEARCH PRODUCTS

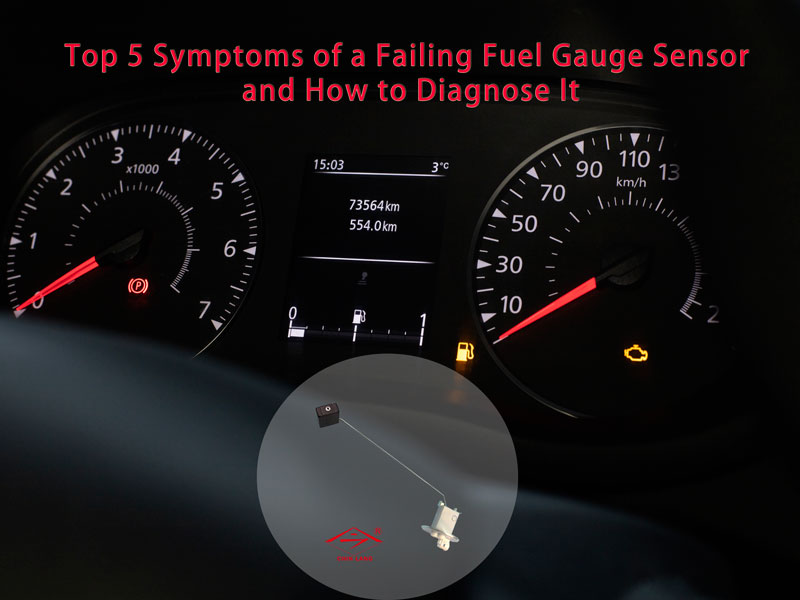

Top 5 Symptoms of a Failing Fuel Gauge Sensor and How to Diagnose It

A fuel gauge sensor plays a vital role in your vehicle's fuel system. It ensures you always know how much fuel remains in your tank—helping avoid inconvenient or dangerous situations like running out of gas on the road. While small in size, this component significantly contributes to driving safety, convenience, and fuel efficiency.

Chin Lang Autoparts, with over 40 years of experience in automotive parts manufacturing and distribution, understands the importance of precise fuel level monitoring. This article explores the most common symptoms of a failing fuel gauge sensor, how to diagnose these issues, and why timely replacement is crucial.

What Is a Fuel Gauge Sensor?

The fuel gauge sensor, often referred to as the fuel sending unit, is located inside the fuel tank. It monitors the fuel level and sends an electrical signal to the dashboard gauge, allowing drivers to view real-time fuel levels.

A typical fuel gauge sensor consists of:

-

Float: Rises and falls with the fuel level.

-

Arm or Lever: Connects the float to the resistor.

-

Variable Resistor (Rheostat): Converts float movement into electrical resistance.

When the float moves, the resistor changes the electrical signal, which the fuel gauge interprets as a specific level. If any part of this mechanism malfunctions, the readings can become unreliable.

1. Fuel Gauge Stuck on Full or Empty

This is one of the most noticeable symptoms of a malfunctioning sensor. If the gauge consistently reads "Full" or "Empty," regardless of actual fuel levels, the issue may lie in the float being stuck or the resistor failing.

Possible causes:

-

Float arm jammed by debris or corrosion

-

Disconnected or damaged internal wiring

-

Open circuit in the variable resistor

Diagnosis Tip:

Remove the fuel sending unit and manually move the float. If the gauge on the dashboard doesn't respond accordingly, the unit may need replacement.

2. Fluctuating or Inaccurate Fuel Readings

If the needle moves erratically or changes without reason, it often points to wear and tear inside the sensor. Corroded contacts or a worn resistor can cause inconsistent electrical signals.

Additional factors:

-

Loose electrical connections

-

Sensor affected by contaminated fuel

-

Wiring harness exposed to vibration or heat damage

Diagnosis Tip:

Use a multimeter to test the resistance range across the sender. Rapid fluctuation or out-of-range values typically confirm a failing unit.

3. Delayed Gauge Response After Refueling

If your fuel gauge doesn't respond promptly after filling the tank, it might be due to a sluggish float or internal sensor lag. While not an immediate threat, this delay can be annoying and misleading.

Diagnosis Tip:

Check if the float moves freely within the tank. A partially soaked or heavy float can react slower than expected, causing delays in signal transmission.

4. Check Engine Light or Fuel Warning Light Turns On

Modern vehicles feature onboard diagnostic (OBD-II) systems that detect irregularities in the fuel system. If the sensor fails or malfunctions, it may trigger a check engine light or a dedicated fuel warning light.

Common related OBD-II codes:

-

P0461 – Fuel level sensor performance

-

P0462 – Fuel level sensor low input

-

P0463 – Fuel level sensor high input

-

P0464 – Intermittent fuel level sensor signal

Diagnosis Tip:

Use an OBD-II scanner to read the exact fault code. If it points to the sensor, further inspection or replacement is required.

5. Running Out of Fuel Unexpectedly

The most severe outcome of a bad fuel gauge sensor is running out of fuel while the dashboard shows there’s still gas in the tank. This is not only inconvenient but also dangerous in highway or remote driving situations.

Prevention Tip:

Keep track of your vehicle’s average mileage and compare it to the fuel gauge behavior. Sudden deviations can be early signs of a failing sender.

Causes of Fuel Gauge Sensor Failure

Several conditions can lead to the degradation or malfunction of the fuel gauge sensor:

-

Aging and Wear: The resistor wears out over time, especially in vehicles with high mileage.

-

Corrosion: Fuel impurities and moisture can corrode internal components.

-

Electrical Problems: Faulty grounding or broken wires disrupt the signal.

-

Float Issues: A damaged or fuel-logged float may not move correctly, leading to inaccurate readings.

Maintenance Tips for Fuel Gauge Sensors

To prolong the lifespan of your sensor, Chin Lang Autoparts recommends the following practices:

-

Keep your fuel tank clean and avoid low-quality fuel that may contain contaminants.

-

Refill before the tank is completely empty to reduce float stress.

-

Inspect sensor connections during routine maintenance.

-

Address dashboard warnings immediately to avoid cascading failures.

Choosing the Right Replacement Fuel Gauge Sensor

Selecting a compatible, high-quality replacement is key to restoring proper functionality. Consider the following factors:

-

Vehicle Make & Model: Confirm fitment to ensure correct readings.

-

Electrical Resistance Range: Must match the dashboard gauge specifications (often measured in ohms).

-

Material Durability: Look for corrosion-resistant, OEM-grade parts.

-

Installation Method: Some sensors are part of a full module; others are standalone units.

If you're unsure, consulting with an experienced parts supplier like Chin Lang Autoparts is the safest choice.

Chin Lang Autoparts: Your Reliable Partner for Fuel Gauge Sensors

As a trusted name in Taiwan's auto parts industry, Chin Lang Autoparts supplies high-quality fuel gauge sensors and related components for passenger cars, commercial vehicles, and trucks. We rigorously test each sensor to meet stringent standards in accuracy, reliability, and durability.

Whether you're an automotive distributor, service center, or repair shop, we offer:

-

Wide compatibility across brands and models

-

Strong resistance to fuel corrosion and wear

-

Consistent performance backed by strict QC procedures

-

Competitive pricing for B2B partners

Final Thoughts

A fuel gauge sensor is a small component with a big responsibility—keeping drivers informed and preventing fuel-related mishaps. By recognizing the symptoms of a failing sensor early and acting promptly, you can avoid unnecessary breakdowns and drive with confidence.

If you’re looking for a dependable supplier of fuel gauge sensors or have questions about compatibility, reach out to Chin Lang Autoparts today. We’re here to help you keep your fleet or business running smoothly.